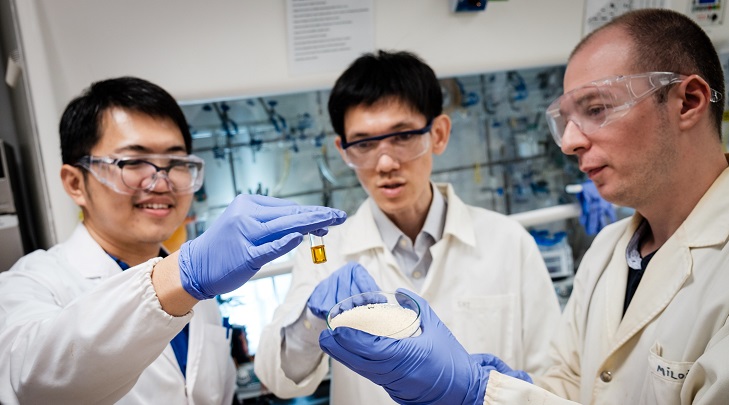

Researchers at NTU Singapore have discovered a vanadium-based photocatalyst that can convert plastic waste into useful chemicals using sunlight.

The team first took polyethylene samples and dissolved them in a solvent at 85°C. A powdered catalyst comprised of vanadium was then added, and the solution exposed to artificial sunlight. Over a period of six days, the photocatalyst broke down the carbon-carbon bonds that make most plastics difficult to break down without high temperatures. The catalyst was specially designed to break these bonds, by latching onto a nearby chemical group known as an alcohol group and using energy absorbed from sunlight to unravel the molecule like a zipper.

Titania photocatalyst recycles CO2 into hydrocarbons

Photocatalyst generates hydrogen from water

Not only does the catalyst break down the stubborn carbon-carbon bonds, the chemicals that the reaction creates are also inherently useful. The process turned the polyethylene into formic acid, a naturally occurring preservative and antibacterial agent, which can also be used for energy generation by power plants and in hydrogen fuel cell vehicles. The research is published in Advanced Science.

“We aimed to develop sustainable and cost-effective methods to harness sunlight to manufacture fuels and other chemical products,” said Assistant Professor Soo Han Sen from NTU’s School of Physical and Mathematical Sciences.

“This new chemical treatment is the first reported process that can completely break down a non-biodegradable plastic such as polyethylene using visible light and a catalyst that does not contain heavy metals.”

According to the team, other advantages of the new photocatalyst are that it is low cost, abundant, and environmentally friendly, unlike common catalysts made from expensive or toxic metals such as platinum, palladium or ruthenium.

Using the method described above, the researchers demonstrated that their photocatalyst was able to break down the carbon-carbon bonds in over 30 different compounds, potentially paving the way for an environmentally friendly, low-cost photocatalyst.

The NTU team is now pursuing improvements to the process that may allow the breakdown of plastics to produce other useful chemical fuels, such as hydrogen gas.

www.theengineer.co.uk